As advanced technology drives farms and factories toward a more efficient future, its relationship with human workers remains unclear. The technologies involved range from the adaptive decision-making abilities of artificial intelligence (AI) to the linear task-completing function of automation. When used effectively, these advanced technologies serve to increase productivity, but may also pose a threat for potential human worker displacement.

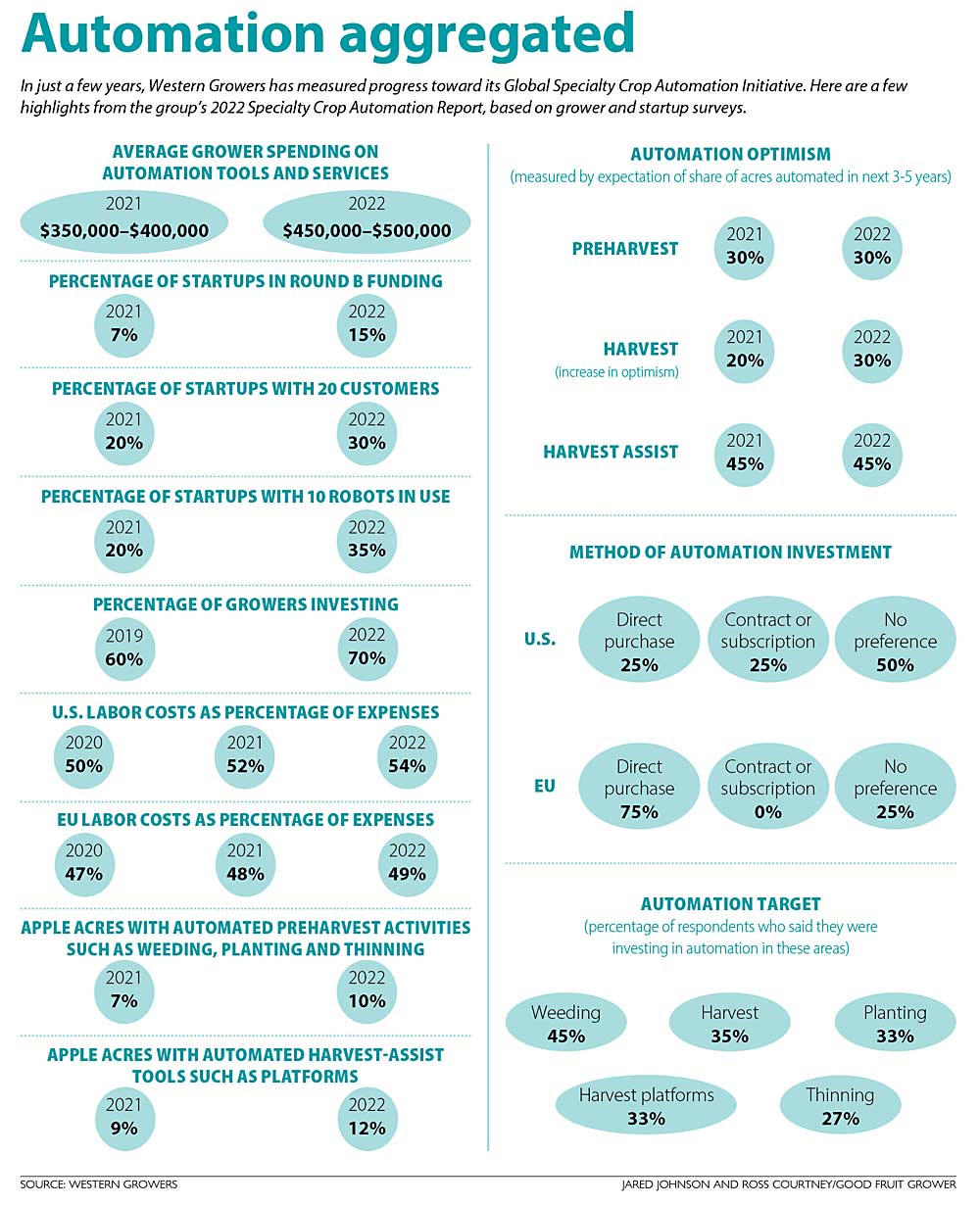

In specialty crops, the use of automation is flourishing. When Western Growers published their 2022 Specialty Crop Automation Report, they found that the percentage of growers investing in advanced technology reached 70%. Between 2021 and 2022, the amount spent by growers on automation jumped 25%, from $400,000 to $500,000. As more innovations are developed, this number is expected to continue growing.

It is undeniable that great strides have been made in streamlining processes in the field and on the factory floor. AI and automation bring benefits including advanced irrigation, labor-free harvesting, meticulous crop inspection, and quality assurance checks. By relying on new technology, companies in agribusiness and consumer-packaged goods (CPG) wield a resource that far surpasses human capabilities.

With such a valuable resource at their fingertips, businesses in agriculture and CPG have to navigate a delicate path that harnesses the efficiency of advanced technology while preserving a connection with human workers. To examine how this balancing act is being carried out, 3P Partners sat down with Cindy Yao, chief financial officer & executive vice president at Markel Food Group; Cameron Boomgaarden, orchard operations manager at Vann Brothers; and Kyle Cobb, co-founder of advanced.farm

Navigating the Landscape of AI in Food and Agriculture

Despite the uncertainty, companies in food and agriculture are finding success with AI and automation in both the field and the factory. Food processing and packing plants have been relying on automation for decades, but introducing AI provides a valuable tool for advanced equipment diagnostics. Plants are now able to accurately determine when equipment will need to be serviced, including maintenance, sanitation, and logistics.

Markel Food Group, which is comprised of AMF Bakery Systems, Reading Bakery Systems, and Solbern, provides automated equipment and technical support for their global customers in the food processing industry. Markel Food Group’s CFO and EVP, Cindy Yao, shared “We design our products to optimize bakery and other food processing processes and machine self-optimization. We want to expand and enhance our offerings by deploying digital and AI solutions applied to our equipment.”

(Source: AMF Bakery Systems)

(Source: AMF Bakery Systems)

At Vann Brothers, Boomgaarden oversees all things tech-based on the ranch, specifically automation from an irrigation perspective. He breaks down the success by sharing how much irrigation automation has grown in a short time.

“We started very small,” he says. “We started with 320 acres, and since 2018, we’ve installed almost 5,000 acres. It is working for us and a lot of other farms.”

The 1462.5% increase in five years speaks to the benefit farms can reap from automating their irrigation systems, but that’s just one part of the picture. Additional benefits exist in vision sorting and grading, with computers processing data significantly faster than humans with an astounding degree of accuracy.

“AI can measure multiple factors of a piece of fruit in ways that humans can’t,” Cobb says. “Whether it’s a visual spectrum that humans don’t have biologically, or just the speed of processing. [Using AI in sorting and grading] will make for better consumer experiences and more efficient farms.”

However, the world of advanced technology in agribusiness isn’t all roses. In certain cases, there can be a marked negative impact, which may lead to lost productivity and a higher cost of ownership when compared to manual labor. One instance of this is using equipment that relies on a strong cellular signal in areas with poor service.

Seeing as most farms are located in rural areas with poor reception, this is a hurdle that needs to be addressed before widespread adoption can take hold.

“When you get into a field with a dense canopy, we do run into a lot of service issues,” Boomgaarden said regarding the use of automated equipment in the field. “It requires a consistent signal, and there’s a lot of mistakes that can be made with a machine of that value spraying a chemical rather than just putting water on the ground.”

Uncertainty Surrounding Advanced Technology

AI and automation are both generally understood, but they are also surrounded by uncertainty. They both work well in the structured environment of factories with unchanging variables, but things aren’t as cut and dry in agriculture.

(Source: advanced.farm)

(Source: advanced.farm)

Trusting AI in the field is still in the early stages, but companies like Kyle Cobb’s advanced.farm are at the forefront of innovation. They are developing software that, when used in conjunction with techniques that add structure to farms, will help automation succeed in the relatively unpredictable arena of agriculture.

“We think the combination of adding structure to those environments and the natural technical progress will really help robots succeed in places that they haven’t before,” Cobb said. “For example, most tree fruit is grown in a trellised, fruiting wall format – that really helps our robots see more fruit, move faster and ultimately pick more fruit.”

(Source: advanced.farm)

Yao summarized, “AI/automation should optimize processes, improve efficiency, and enhance decision-making by removing added complexity.”

But in the landscape of rapidly progressing technology, workers find themselves wary of being replaced. Education and communication are Cameron Boomgaarden’s key recommendations for managing the concerns of the workforce being replaced. The idea is to engage in early discussions about how AI and automation will be used in hopes of avoiding skepticism.

“With any sort of technology, buy-in is key,” Boomgaarden says. “We took the time to hear what the problems are. We tried to get a general understanding of how the system is run manually and discussed the biggest headaches that we can alleviate with automation.”

Conversations that involve the workforce in the implementation process serve to dispel fears of replacement while promoting the benefits of AI. By engaging openly and honestly with workers, operations managers and others in charge of incorporating these technologies can demonstrate that they are working with the employees rather than against them.

Can Workers and AI Coexist?

Advanced technology has an undeniable effect on human workforces, and fear of displacement has existed since automation first hit factory floors in the 1950s. While automation is designed to reduce headcount, it did not completely replace factory workers. The same appears to be true with AI and 21st century automation, and the human touch remains a crucial element in performing a job well done.

Boomgaarden expresses optimism that humans are necessary for finer decision making. “It’s difficult to rely on AI to make decisions,” he says. “We’re under the impression that there’s really no substitute for somebody that’s making the decisions in the field. [We want to] have more boots on the ground and use the technologies as tools rather than decision makers.”

Although the introduction of these advanced technologies is removing certain roles, it is not a net loss because new roles are being introduced to help the technology function. People with new skill sets are now required on farms and in CPG factories to help maintain the machines, oversee their operation, and analyze the influx of data.

“There’s certainly a trend of people who have a genuine interest in data science,” Cobb says. “I think that’s a new field [in agribusiness] that hasn’t been around until very recently.”

Aside from introducing new roles into the workforce, advanced technology is also seen to improve the work-life balance for existing employees. It allows for a greater separation from day-to-day manual tasks, which Boomgaarden notes among the irrigation staff at Vann Brothers.

“It allows our labor force to be far more efficient,” he says. “We can do more with less, and it’s not as taxing on our employees. It frees up our employees so that they don’t have to come in late or on the weekends to adjust the irrigation systems.”

Safety Concerns with AI and Automation

In addition to concerns about worker displacement, integrating AI into the workforce raises questions regarding safety, namely cybersecurity and worker safety.

Cybersecurity will always be a concern with the introduction of devices that wirelessly share information with each other using a network connection. Finding ways to securely operate connected equipment without the risk of privacy breaches or lapses in functionality will be vital for sustained operation. Although the potential for security risks may seem negative, it produces the need for information security and introduces yet another job function that did not previously exist in agribusiness.

Physical safety for workers in the field proves to be another concern when implementing new technologies. Dangerous possibilities exist when humans and autonomous equipment operate in the same environment, and safety protocols will need to be strongly considered if humans and AI are to coexist in the workplace.

At advanced.farm, Kyle Cobb is noting creative ways that operations managers can promote the safety of workers and improve the efficiency of AI, all while preserving the human element.

“People are going to have to cordon off parts of the farm that are specific to autonomy, and then after the machines are done, the humans can come in and do their work,” he says. “Or maybe the humans set it up before so that the machines can perform really well.”

Automated harvesting technology from advanced.farm

Having humans perform prep work, such as clearing obstacles and obstructions, will allow the technology to perform at a peak level without completely removing the human element from the process.

And while some companies are practicing safety by putting a certain distance between humans and autonomous equipment, Cindy Yao praises the ability of AI to keep her workers safe by relying on automation in situations that would be dangerous for human workers.

“Using AI and automation is about enhancing the human working experience to incorporating that into existing workflows,” Yao said. “[I believe that] AI and automation were designed to eliminate the 3D’s: dull, dangerous, and dirty tasks. We need to focus on training our people for more value-added tasks.”

Moving into the Future of Agribusiness and CPG

The way that food and agriculture businesses operate is changing. Advances in technology are fueling innovations in the workplace, and whether companies are ready or not, AI and automation are coming. Companies that fail to adapt to progressing technology may find themselves on the outside looking in as their contemporaries move forward with greater efficiency and productivity.

“Long term, automation to any degree is going to be something that is at the forefront of agriculture,” Boomgaarden says. “I think it’s imperative for the success of any business small or large, to begin to at least look into automation or deploy it to some degree.”

AI and automation have risen to prominence on farms for their ability to reduce worker fatigue by streamlining irrigation and improving crop inspection. In factories, AI is helping track contaminants on production lines and reduce waste. However, despite these benefits, improvements will need to be made before widespread adoption is realized.

Even after advanced technology is functioning without downtime or fear of inaccurate on-the-fly decision making, it appears that the human element will remain a constant part of the workforce in food manufacturing and agricultural production. The introduction of technologies will create additional jobs that did not previously exist in the food and agriculture space, and experts believe that there will never be a substitute for the watchful eye and snap judgments that only humans are capable of.

Cameron Boomgaarden | Vann Brothers

Cameron Boomgaarden is the orchard operations manager at Vann Brothers Farming, a grower of more than 17,000 acres of high-quality almonds. Cameron has worked in the almond industry for five years, with a particular focus on water management and technology. Vann Brothers Farming is the farming operation under the Vann Family umbrella along with Vann Family Orchards and Yolo Hulling and Shelling. VBF grows almonds with a commitment to sustainability and continuous improvement. VBF states that operating a sustainable business is not a project with a defined end— it is an ongoing journey with continuous improvements and the embracing of transparency. Their view of sustainability means they cannot seek economic gain at the expense of environmental stewardship or community.

Cindy Yao | Markel Food Group

Cindy Yao has over 20 years of finance experience in the manufacturing industry. Cindy joined Markel Food Group in 2013 as Chief Financial Officer and has expanded her role also as EVP of Markel Food Group. She was recently awarded Virginia’s CFO of the Year. Markel Food Group is a global leader in automated food processing solutions and comprised of three wholly owned operating companies that deliver high-quality automation solutions to food producers around the world. The company is enabled through the development of its people to create market leading products for the industrial food industry and beyond. The Markel Food Group Business System or (MBS) defines the company’s core values and the strategic processes they have put in place within each of their companies

Kyle Cobb | advanced.farm

Kyle Cobb has over 15 years of experience in corporate strategy and product development. In 2018, Kyle embarked on a transformative journey, co-founding advanced.farm, a pioneering startup headquartered in Davis. This dynamic company is at the vanguard of agricultural innovation, crafting state-of-the-art robotic farm machinery poised to define the future of the industry. In a groundbreaking stride in 2019, advanced.farm achieved a remarkable milestone by becoming the inaugural U.S. entity to successfully bring robotic strawberry harvesting to the commercial realm. The company is guided by their vision of a “new frontier in farming: where human grit and determination meets automation, and farms are made safer, better, and more productive.”